On Monday morning, the new engineer needed to register his children in school, so we delayed the training session until after lunch. This session covered the HC100 power distribution and cooling systems.

The blower which provides positive pressure ventilation and cooling to the building was vibrating terribly when we arrived this Monday. It was discovered that one half of the two belt variable pulley was askew and its associated belt was the source of the vibration. The motor was shut off and the belts removed. The half of the pulley that was askew had apparently ‘stripped’ its threads on one side and was tilted. I have never seen this happen before. The only explanation seems to point to the one setscrew slightly loosening over time. The opposite side could them ‘wobble’ just a bit and over time the threads on the opposite side were worn away. Anyway, that half of the pulley was removed and only one belt was used until another pulley could be ordered. Since the motor has a variable speed drive with reduced starting torques the double belt was not a necessity. A fixed two belt pulley was ordered as a replacement and installed later in the week.

The low level Optimod noise mentioned last week was not there when we tried to investigate it further Monday afternoon.

Tuesday morning the training session was on the HC100 tuning system and phase detectors. The new engineer was not feeling well and left at noon. In the evening, just before leaving for home we noticed that the low level Optimod noise had returned! After supper, I worked on the draft for our June McGuiReport.

Wednesday morning we attended the weekly staff meeting and had the rest of the day off. The next two Wednesdays of May we will be working after staff meeting and make the trip to the site. After staff meeting I took Virginia shopping, since she doesn’t have the courage yet to drive on the left side of the road in such hectic traffic.

Since our McGuiReport is due for proofreading this day, I finished the final touches and sent it to TWR Cary. Somewhere in the middle of the process, I took a quick nap upon getting too drowsy to think clearly.

The road was graded this afternoon, since it was still reasonably soft after the rains last week. According to the other missionaries, it has been a long time since it was done. Now there are only a few potholes and washouts in the one mile drive (its seems much longer) to the tarred road. Wonder how long that will last?

The evening was spent studying the metering section of the HC10o manual. For me, it is requiring more review, since it deals with generating data for computer control of the transmitter.

Thursday morning was spent teaching the metering system and interacting with the other engineers and technicians. Its amazing how much is learned by everyone, especially by me! This information was timely as in the afternoon we began trouble shooting a metering problem that was noticed the day before. We discovered that a meter driver card had switches on it that were not properly selected, but did not have time to rectify the problem because the transmitter was due to go on the air. I began to suspect that the two meter driver cards had been swapped, but would have to wait for the next day to verify. In the evening, I reviewed the control system, which requires even more computer knowledge, which means it is even more challenging for me than the metering system was.

Some urgent station repairs required on Friday caused the training session to be put off for the day. There was a problem with the slew switch on the largest antenna, which resulted in it switching continuously without stopping in the desired position. The slew switch ‘slews’, or redirects, the main beam of the antenna slightly to the right, or to the left, of center to direct a stronger signal to a target audience in that direction. After some troubleshooting, it was discovered that one of the wires that carried the signal of a limit switch was open circuit. Unfortunately, that wire was 1000 feet (about 300 meters) long and buried underground! Several years ago, the original cable that had been buried in 1978 had failed. It had been replaced with three runs of house wiring suitable for underground use. Only

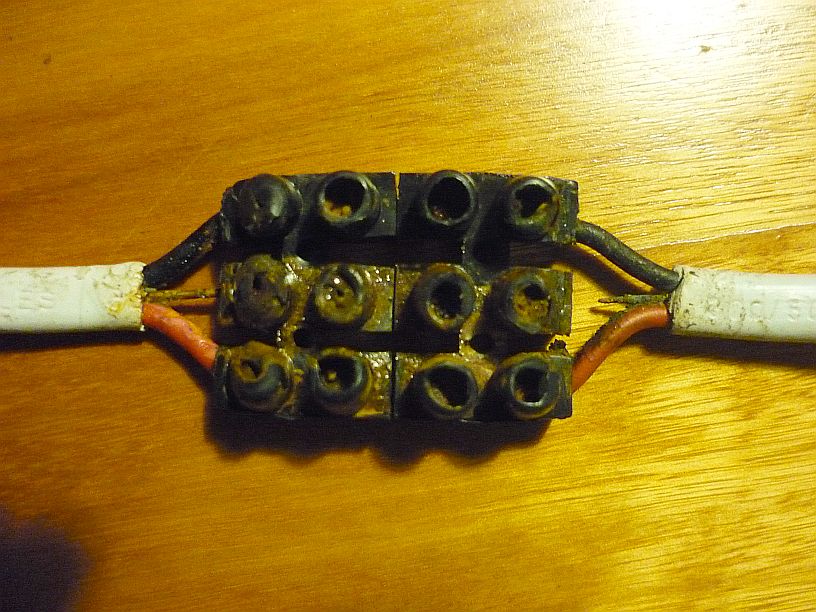

100 meter lengths were easily available, so two splices were were required in each run. It was thought one of the splices had failed. It was easy to see where the line was buried, so 100 meters was measured off from the building and the digging began. No splice was found there, so the trench was extended back towards the building. Fortunately, it was easy digging as about 50 feet was dug up before the splices were found. Also the splices were marked, so the suspect line was easily isolated. The fact that water was seeping into only this section of the now, rather long, shallow trench provided evidence that the fault might the here. Since the splice was encased in a 6 inch long plastic pipe filled with epoxy, the only alternative was to cut the wire on either side of the splice.

The splice was then measured and found to be open circuit. This was a good thing, otherwise it would have been necessary to move down the line 100 meters and dig up the next set of splices. A temporary jumper, now with two splices, was connected and draped over pieces of wood across the trench to keep the temporary splices, and the other two splices out of the water. The slew switch now worked. A continuous 1000 foot length of 7 conductor cable with armored underground jacket has been ordered to eliminate all underground splices. It should take about a week for it to get to Swaziland from Johannesburg, South Africa. It is quite pricey, but should be worth it, as the other splices could fail at any time.

While others were doing the repair, I took the old splice into the shop and cut the plastic tubing off, then broke the epoxy off with a hammer. Some water had seeped into the splice, even with the epoxy encapsulation. We actually thought the problem was going to be in the actual splice, but one of the three wires had corroded away right next to the splice.

After the cable repair, our attention was focused on the metering card problem isolated on Thursday. Sure enough, after close inspection of the 32 data switches on the two meter driver cards and figuring out how each should be set, they had been swapped in location. It did not effect the operation of the transmitter at all, but sure gave confusing meter readings.

Virginia and I relaxed this evening and played several games of Rummikub.

After a busy week, we were lazy on Saturday morning and I did some paperwork that had been put off. In the afternoon I took Virginia to a ladies’ meeting at the church.